Peristaltic pumps deliver accurate doses of fluid while isolating the fluid from the pump components, making them an ideal choice for precision dosing requirements and applications sensitive to contamination such as food production and chemicals (e.g. paints, lubricants) mixing.

While there is a plethora of choices on peristaltic pump heads, most pump controllers available come with complex user interface designs requiring highly trained users and rarely allow customisation/ expansion.

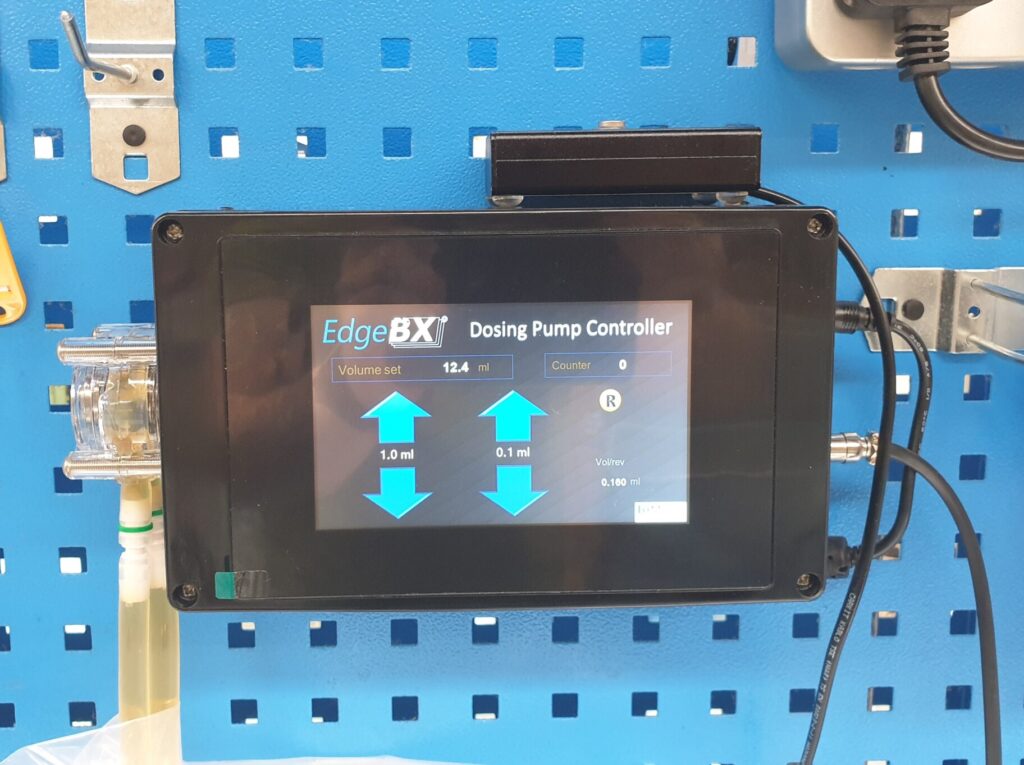

The EdgeBX fluid dispensing systems allow manual control through a local colour touch screen display and a mobile-friendly remote application or automatically by a central control system.

The interface allows for easy volume setting and offers a range of "trigger" options to start dispensing such as;

The system can be easily calibrated for various fluids. The setting can be in volume of mass.

For applications requiring high precision, the system can be paired with flow and mass sensors to provide instant feedback and apply corrections to its calibration.

Contact: info@edgebx.co.uk for more information.