IoMech is proud to announce the successful implementation of the EdgeBX® test controller for conducting Aerospace Qualification Testing for a Tier-1 Aerospace suppliers at a TUV-SUD test facility.

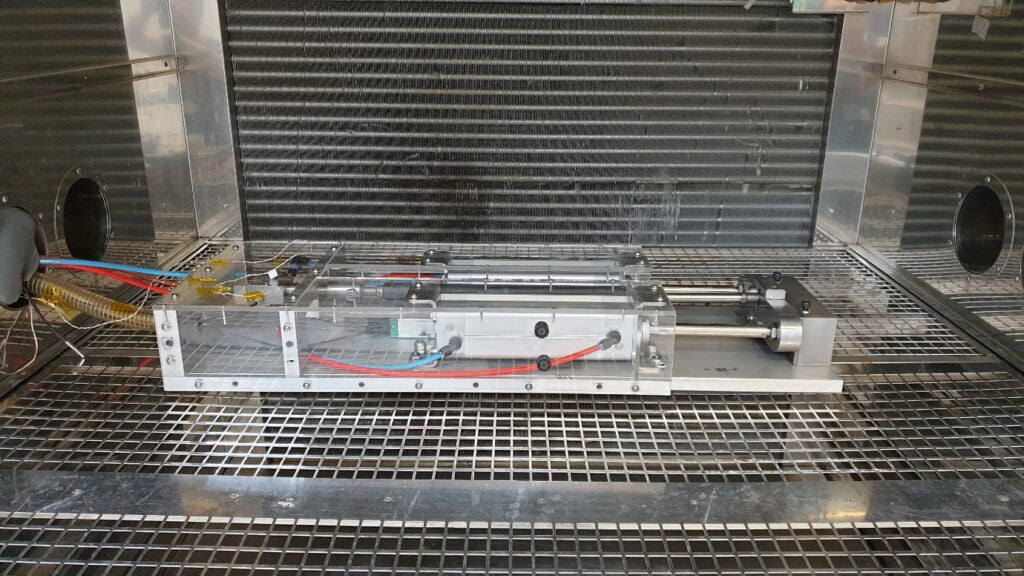

The product is intended for use on a new-generation fighter-jet project, requiring prolonged Environmental Testing at conditions ranging from -54 to 90˚C (MIL-STD-810G, Methods 502.5, and 520.3).

The controller's Touch Screen User Interface allowed programming the test rig to run a specific number of cycles, at a specified frequency, when the chamber temperature meets specified conditions (event-based). While time-based sequence programming is possible, such approach eliminates synchronisation problems between the chamber and the test controller.

Once the test conditions were set, the touch-screen User Interface (UI) allowed activating the test rig and monitoring the sensor values during the final stages of the test setup.

The operation of the EdgeBX® test controller is shown in the video below:

During testing, the sensor data, test state (e.g., “-19˚C soaking”), and cycle number are:

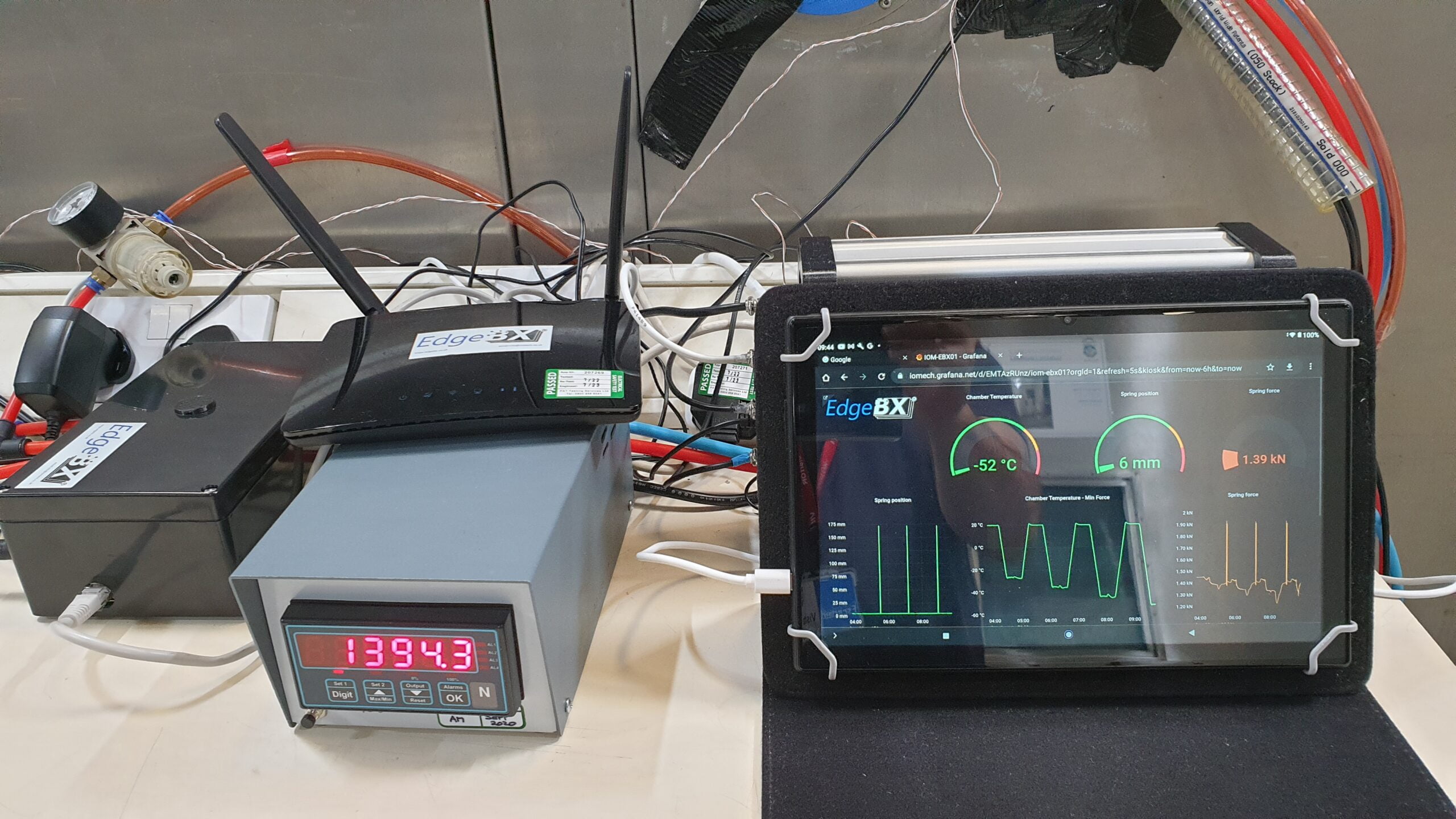

The image below shows a tablet connected to the EdgeBX® cloud dashboard during low-temperature testing (MIL-STD-810G, Method 502.5). A snapshot of the test dashboard can be accessed from here

The two-week testing was conducted as planned, without interruptions and needing supervision or interventions during the continuous testing.

The EdgeBX® cloud dashboard allowed remote test monitoring at any time during the process.

Following the positive feedback and recommendations from TUV Environmental Engineers, we are now developing a new “test editor” screen to allow users to program the controller for a wide range of sensors and test scenarios.