Upgrading test equipment with EdgeBX SUI units

We are proud to announce the successful delivery of a complete EdgeBX® IoT system:

An array of custom EdgeBX® SUI (7" touch-screen display) units were utilised to upgrade all force testing machines in a gas spring manufacturing facility from "indication only" equipment, to a set of interconnected test units capable of collecting product information through a barcode/QR code scanner and test data through a set of sensors.

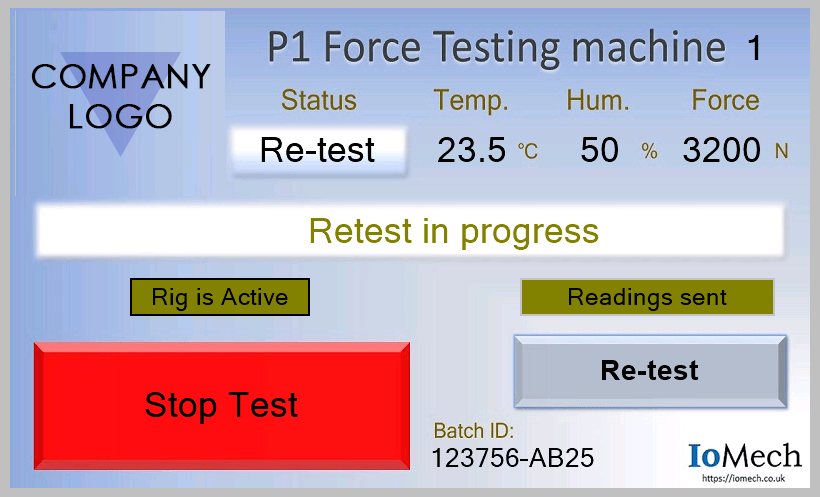

The User Interface was designed in liaison with the Company's management team and the machine operators to ensure that the system provides an optimal solution to the organisation's current needs while allows scaling up to possible future expansions.

The EdgeBX®-SUI units fully control each test machine to ensure that the operators scan the product ID barcode before starting a test and feature three different states of the testing process, namely "setup", "testing" and "re-testing".

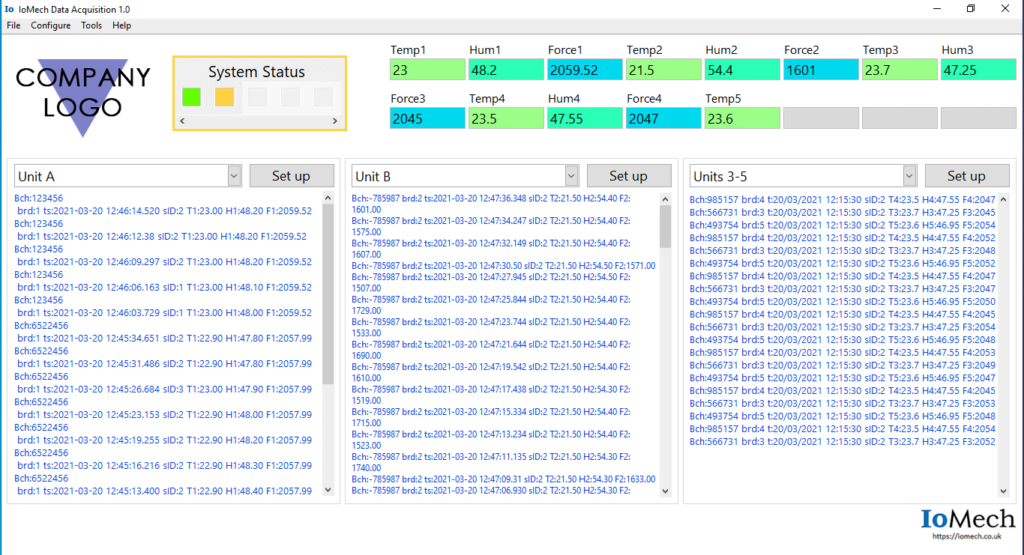

At the end of each test cycle, the EdgeBX® units send all relevant information such as product and batch ID, force and temperature values, time/date and state ID (e.g."re-test") to the LabView-based, IoMech data aggregation software installed on a windows PC.

The data aggregation software provides a user-configurable dashboard for viewing (almost) real-time data from all EdgeBX® units (test machines and any other upgraded equipment) while logging all data in a local network database.

The benefits of this upgrade include: