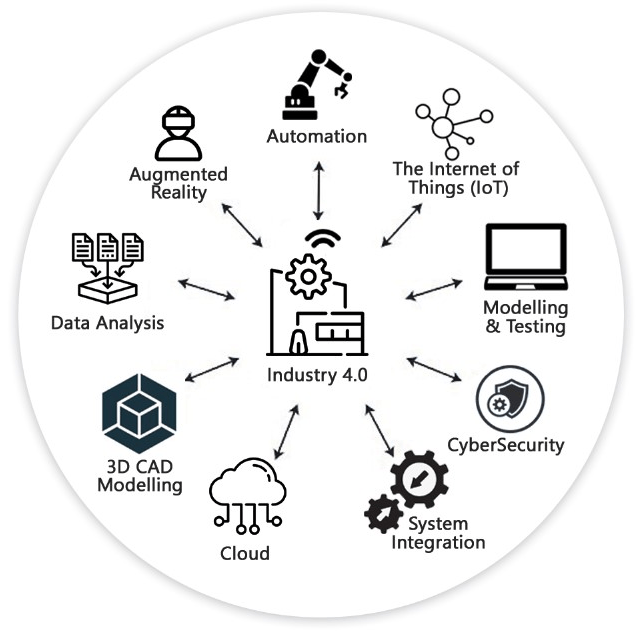

Industry4.0 or the “Fourth Industrial Revolution” involves the integration of machine-to-machine (M2M) communication and the Internet of Things (IoT) to increase automation, communication and Self-monitoring. Lean, Six Sigma and Quality Management systems such as ISO 9001/AS9100 require organisations to acquire and analyse key process (e.g. assembly, manufacturing) metrics, in order to enable evidence-based decision making. Considering the amounts of data required to monitor the KPIs for various business processes, the implementation of automated data collection systems and is essential for adopting such practices.

Industrial IoT systems can benefit manufacturing organisations by:

The primary entry barriers to adopting the Industry4.0 / Industrial IoT approach are:

IoMech can help you to overcome common entry barriers: